Power Balance

The solar system on the roof of the Sunglider Metro is a remarkable power plant. Under climate conditions of 2018 in Osnabruck, it would generate about 211,000,000 kWh of electricity. This would correspond to the power consumption of 65,000 four-person households in Osnabruck (source: www.co2online.de).

The estimated energy balance of the Sunglider above shows: all vehicles including e-bikes, the stations and the street lighting consume all about 180,000,000 kWh. That is 31,000,000 kWh more than the metro needs. This amount of electricity the operator can sell. With a price for the kWh of € 0.35 (in 2030), this results in an annual income of € 10,850,000. The revenue from the sale of CO2 certificates, however, is not included here.

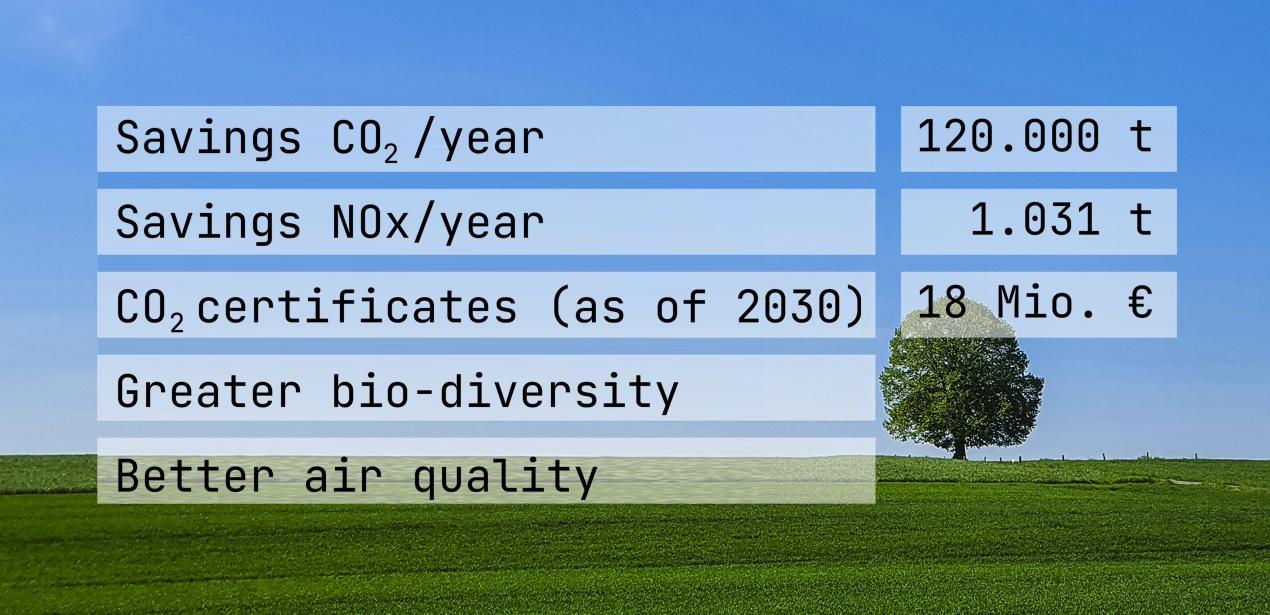

Eco Balance

With its photoelectric drive, the Sunglider can look at a remarkable ecological balance. The amount of CO2 saved is as expected about 120,000 t a year, the savings in nitrogen oxide (NOx) are surprisingly high (1031 t). Other ecological advantages are obvious, but difficult to quantify: Better air quality, higher biodiversity, fewer accidents, more shade in those cities that are warming up due to climate change, more water under the solar roof, newly conquered urban space and much more!

One item, however, can be quantified very well: the value of the CO2 certificates, the proceeds of which for 2030 are estimated in the chart above at a cautious €150.00/t.

Amazing economy

Drastically falling manufacturing costs, low costs in the construction of the route, new construction forms, the latest developments in elevator production, further falling costs for PV modules and intelligent solutions for energy distribution, all this leads to amazing system-investment-costs per mile that are significantly lower compared to trams and 10 times below the investment in urban subways. At the same time, the operating and maintenance costs are lower than with any other public transport system in the world thanks to the massive savings in energy and personnel. This is offset by financial potentials created by the selling of 30,000 MWh of power to the market and the sale of CO2 certificates.

All this is unprecedented – not only in public transport. If you add the income from the cargo business, from merchandising and the sale of third-party tickets, you can prove that the Sunglider can really offer a zero tariffs transport system and still earn money.